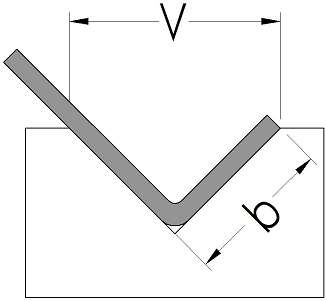

So if the metal plate is 75 thick you would multiply 4 x 75 3 so your minimum inside bend radius would be roughly 3 times the thickness of the material in this case or 2 25.

Minimum bend radius stainless steel sheet.

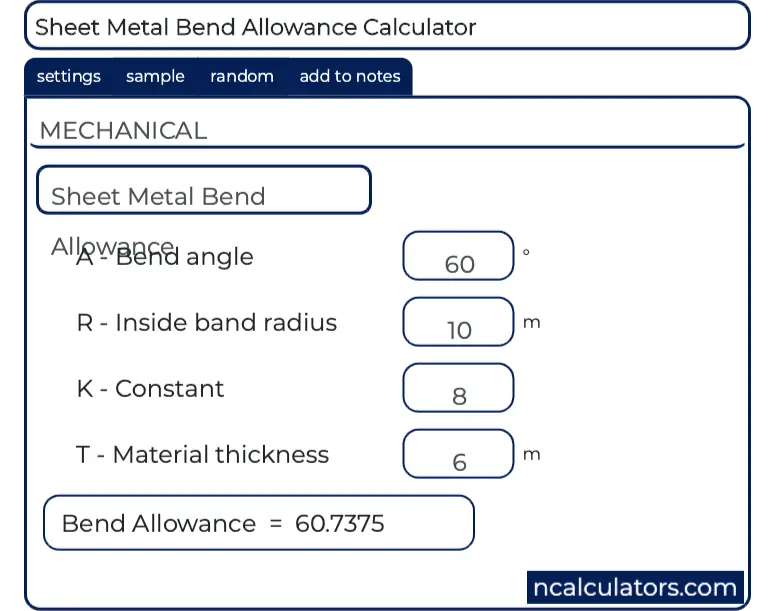

Discover all our calculation tools in the calculators section of the top menu.

Being able to read a bend force chart is crucial for any brake press operator and sheet metal engineer.

Steel or stainless steel.

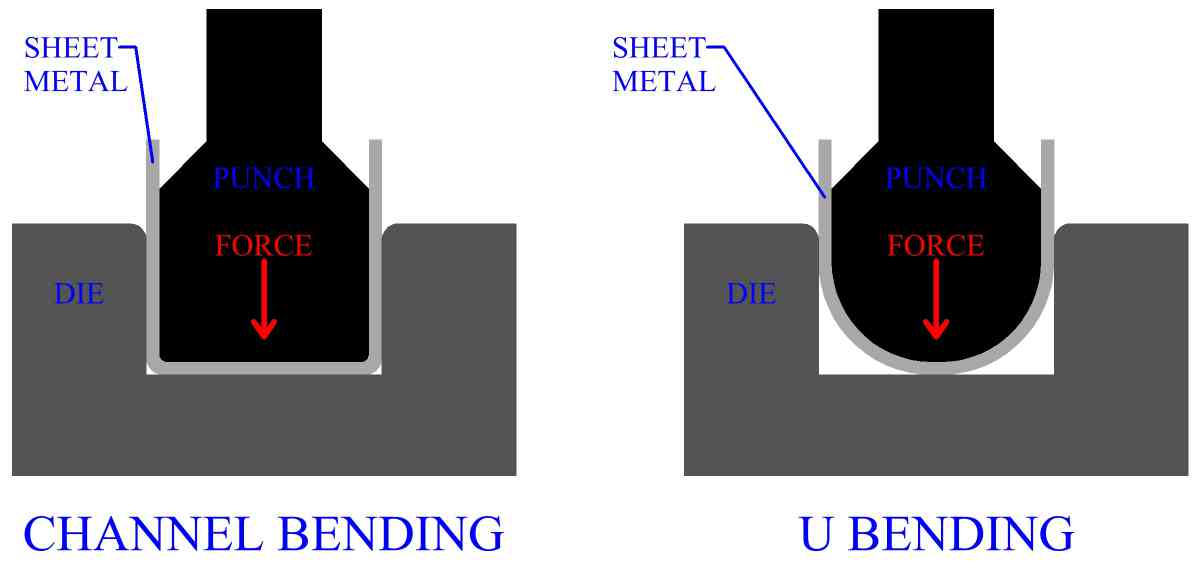

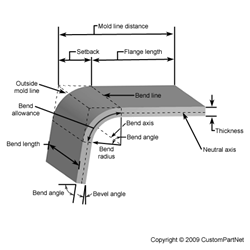

The gauge inside radius die opening and minimum flange length are all interconnected through different equations and relationships the air bend force.

Minimum bend radius annealed to 4 75 mm 0 5t for 180 degree bend.

This tool allows you to determine tonnage internal radius v die opening and minimum flange you just have to insert the characteristics of the sheet metal to be bent.

Thick grade 350 and 400 may have a minimum bend radius of 2 5 times the material thickness when transverse bending while longitudinal bending may require a minimum bend radius that s 3 75 times the material thickness see figure 1.

When bending 6061 aluminum the minimum inside bend radius should be 6x the material thickness otherwise cracking is likely to occur during bending.

The tool can calculate the required bending force for bending aluminum stainless steel mild steel and weldox or strenx high strength steels.

Also note that all these are just examples.

In steel between 0 5 and 0 8 in.

Actual minimum radius values vary by grade.

The minimum inside bend radius is even larger when bending with the grain.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

However it is important to know that this is just a broadly applicable rule of thumb you can follow for making bends in steel.

Minimum bend includes minimum closeness of cutout to bend radius cold rolled steel 14 gauge 0 075 1 91mm.

Preferred recommended 90 degree bend radii for various sheet metals.

If it is in the fully annealed condition then 1t bends can be done.

An air bend force chart or force chart breaks down a number of key components of sheet metal bending in an easy to reference format.

1 steels with lower carbon content are easier to weld and form.

Aluminum 5052 or 3003 take note.

Strain hardened 1 4 hard 1 2 hard etc.

10 carbon content may be bent back on itself in any direction without cracking.

Grain direction is formed in metal in the direction in which the sheet was rolled at the steel mill.

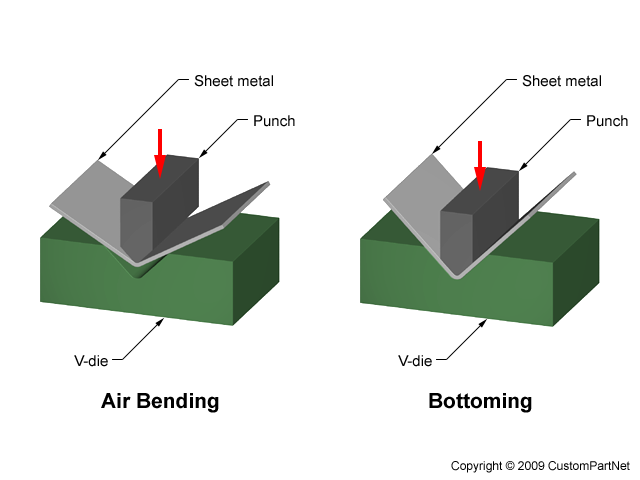

The following tables showing the minimum bend radius allowable in air bending process for aluminum and steel or stainless steel.

The following are typical bending limits for types 301 302 304 stainless steel.

You did not indicate in what condition the stainless steel would be.