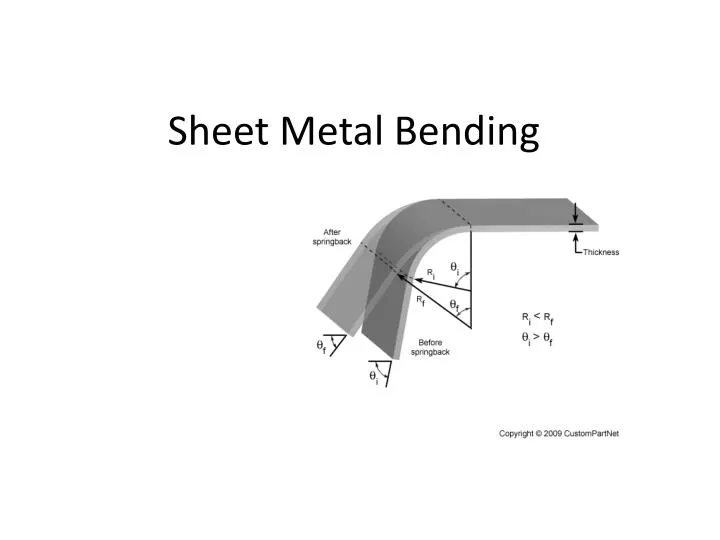

A method of bending sheet material by use of complimentary male punch and female molding members said female molding.

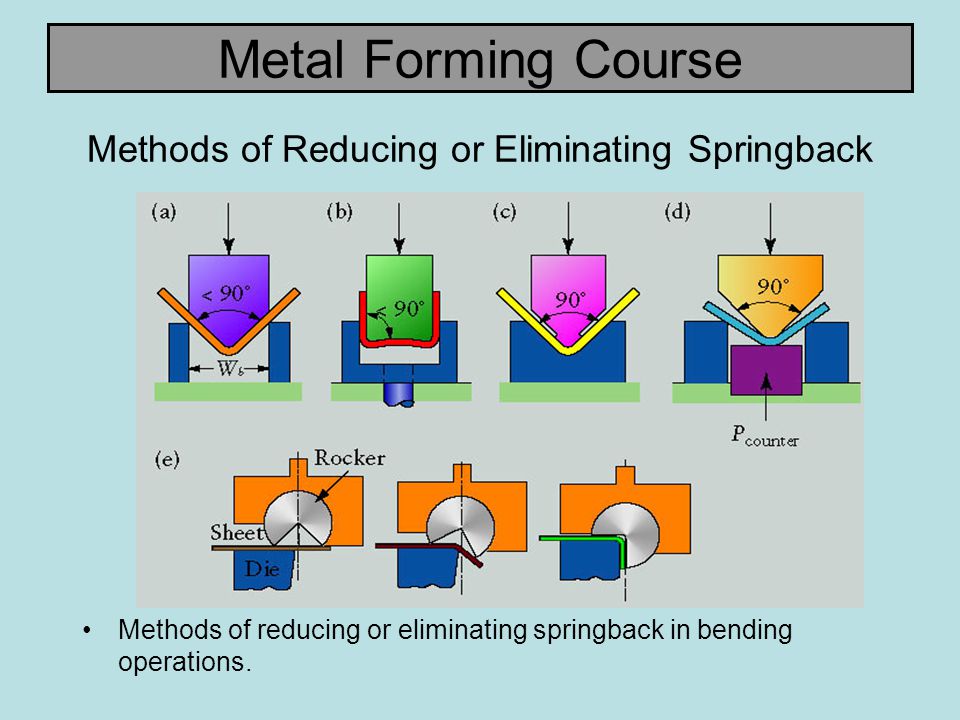

Methods of reducing springback in sheet metal operations.

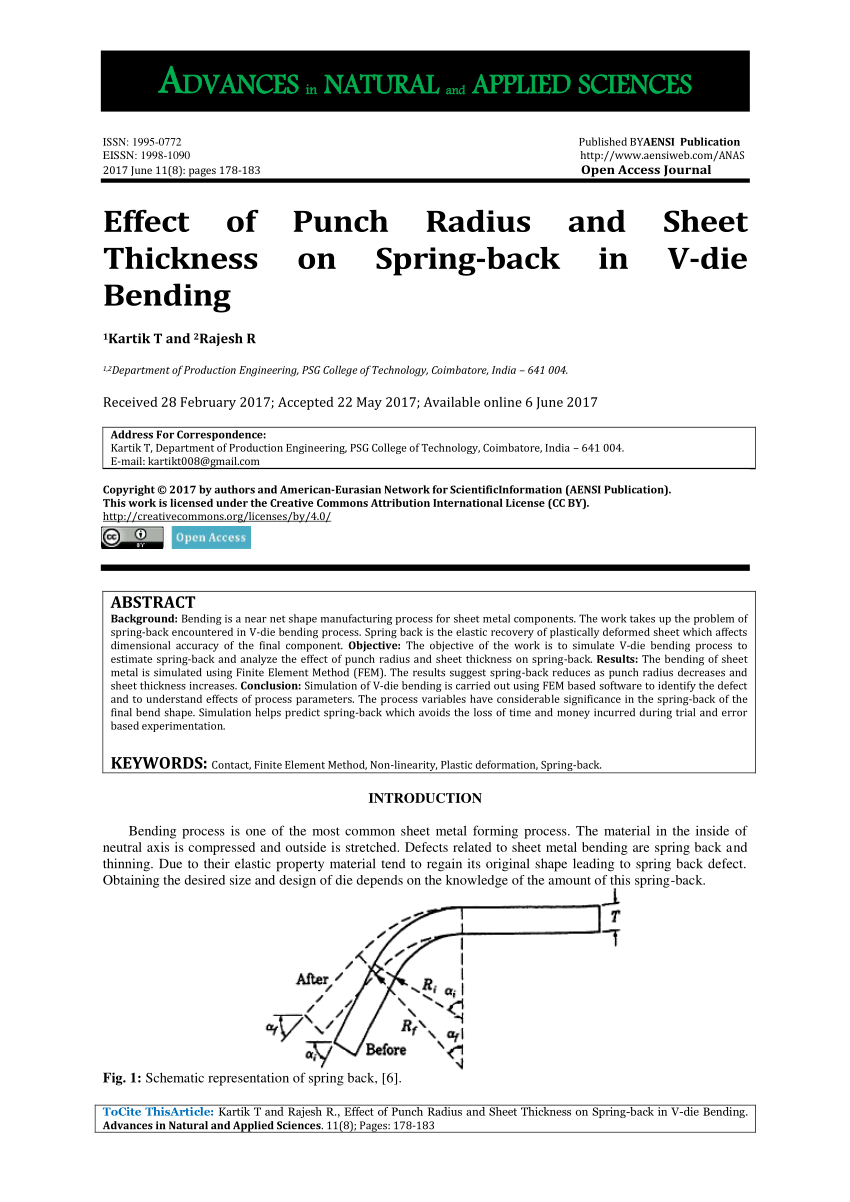

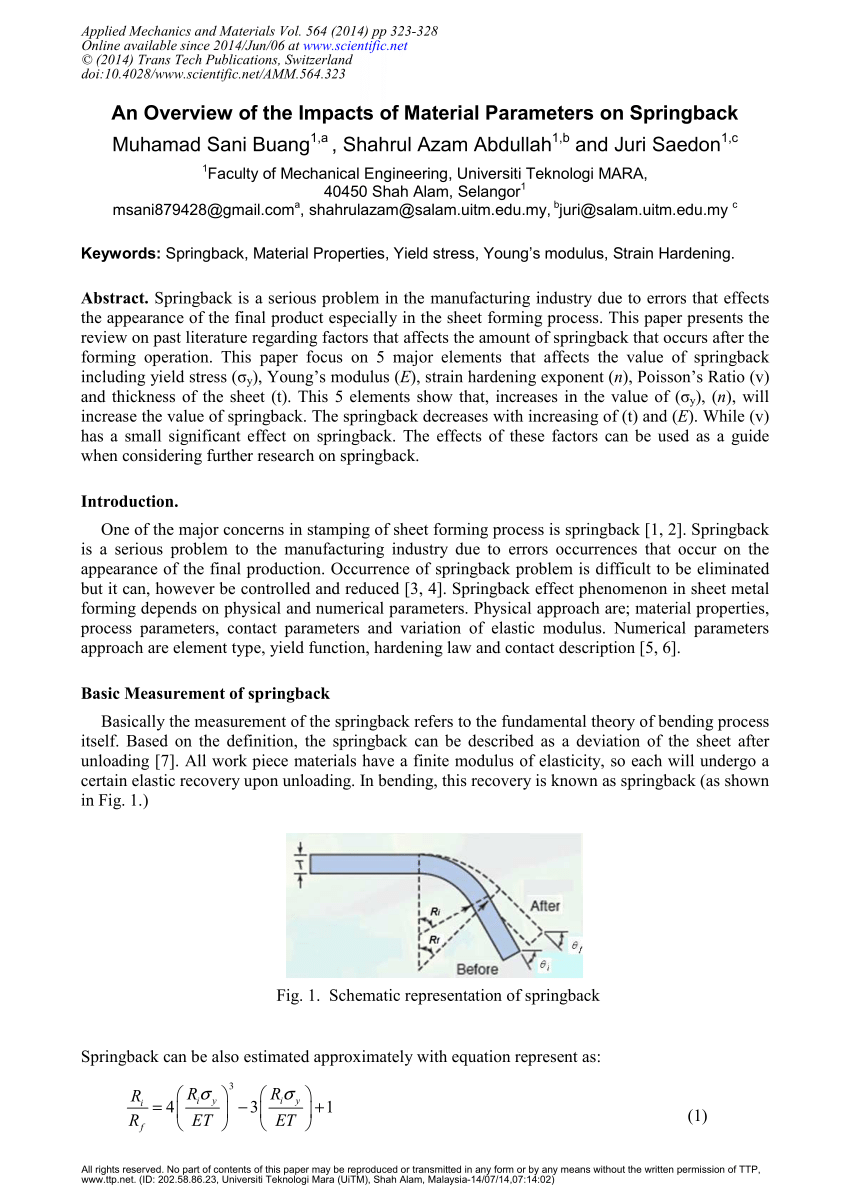

In this paper a die shape optimization method for reduction of spring back defect due to elastic recovery behaviour in sheet metal bending process is presented by using the reduced basis.

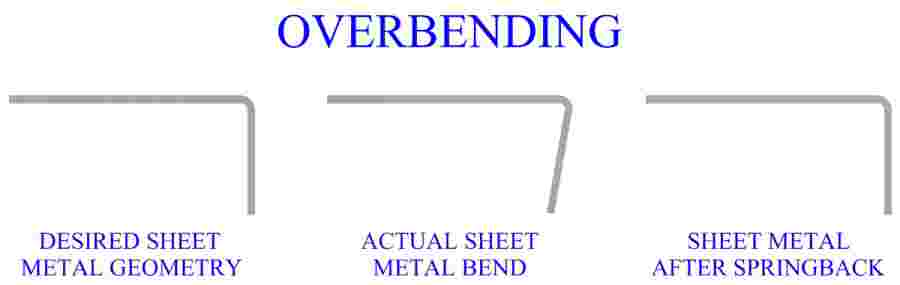

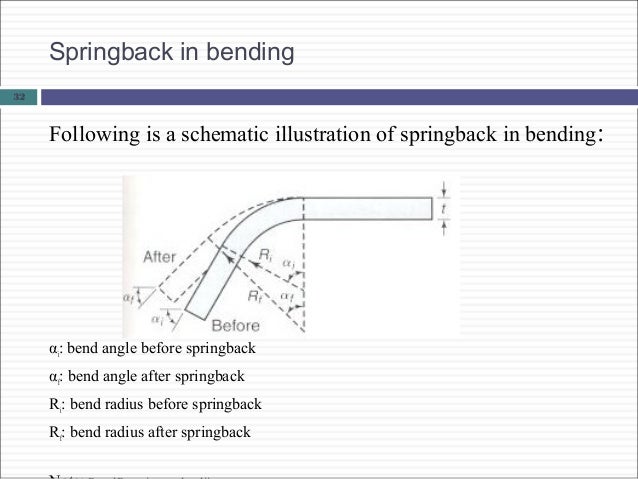

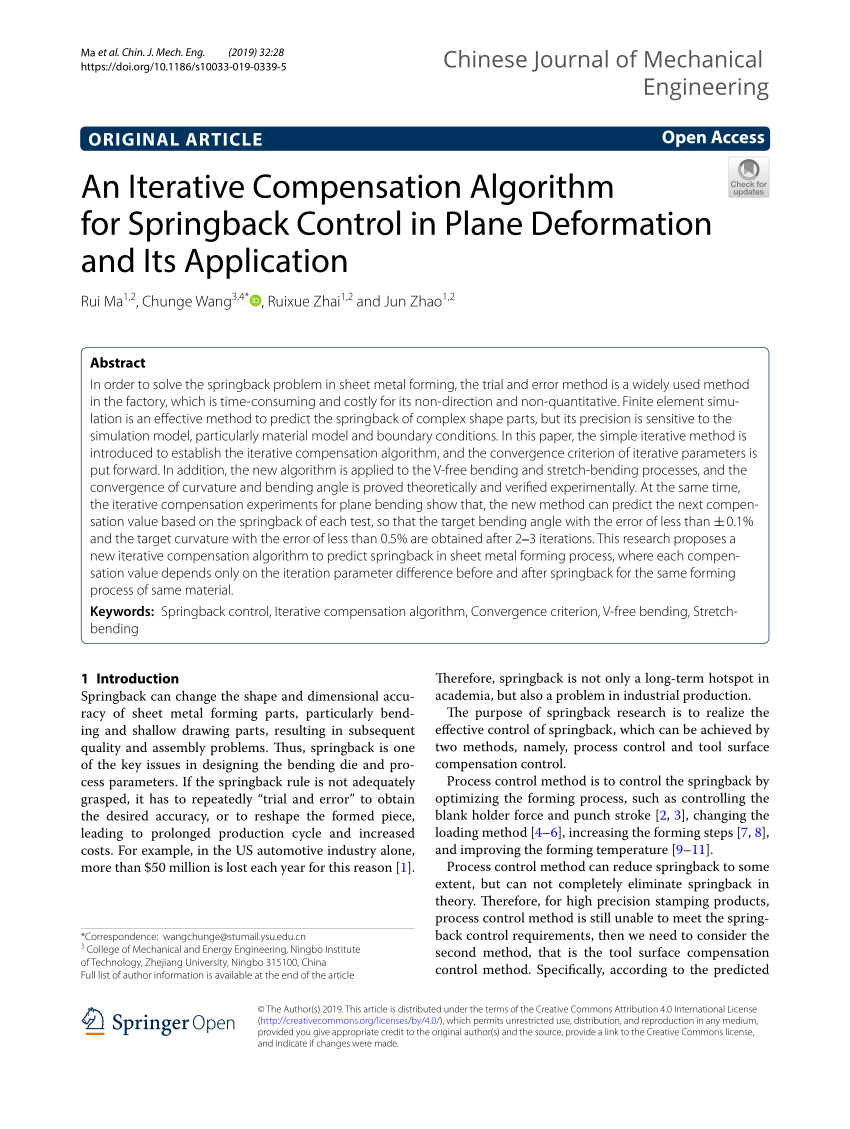

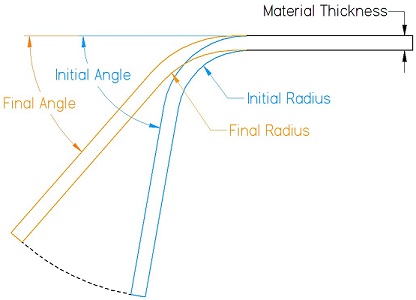

After adjustment both inner and outer layers are elongated and the springback trend of the two areas after unloading can be offset to reduce the springback.

This paper analyzed the mechanism of deep drawing springback of sheet metal forming and the springback compensation was studied.

Method of reducing springback in mechanically pressed sheet materials i 1.

Heat treatment anneal before bending to reduce hardness and yield stress which can not only reduce rebound but also reduce bending force.

The results show a good reduction in springback but this method is applied and tested in the l bending only.

The u bending model is analyzed by slota et al.

In both numerical and experimental analyses.

The experimental analysis is conducted by using specimens of steel dc06 uhss trip rak 40 70 and hss h220pd in orientations 0 45 and 90.

It is found that the cold punch combined with the hot die can reduce the springback up to 20 when compared to conventional room temperature bending test in the sheet forming process of u bend aluminum 1050.

A springback reduction method for sheet metal bending abstract.

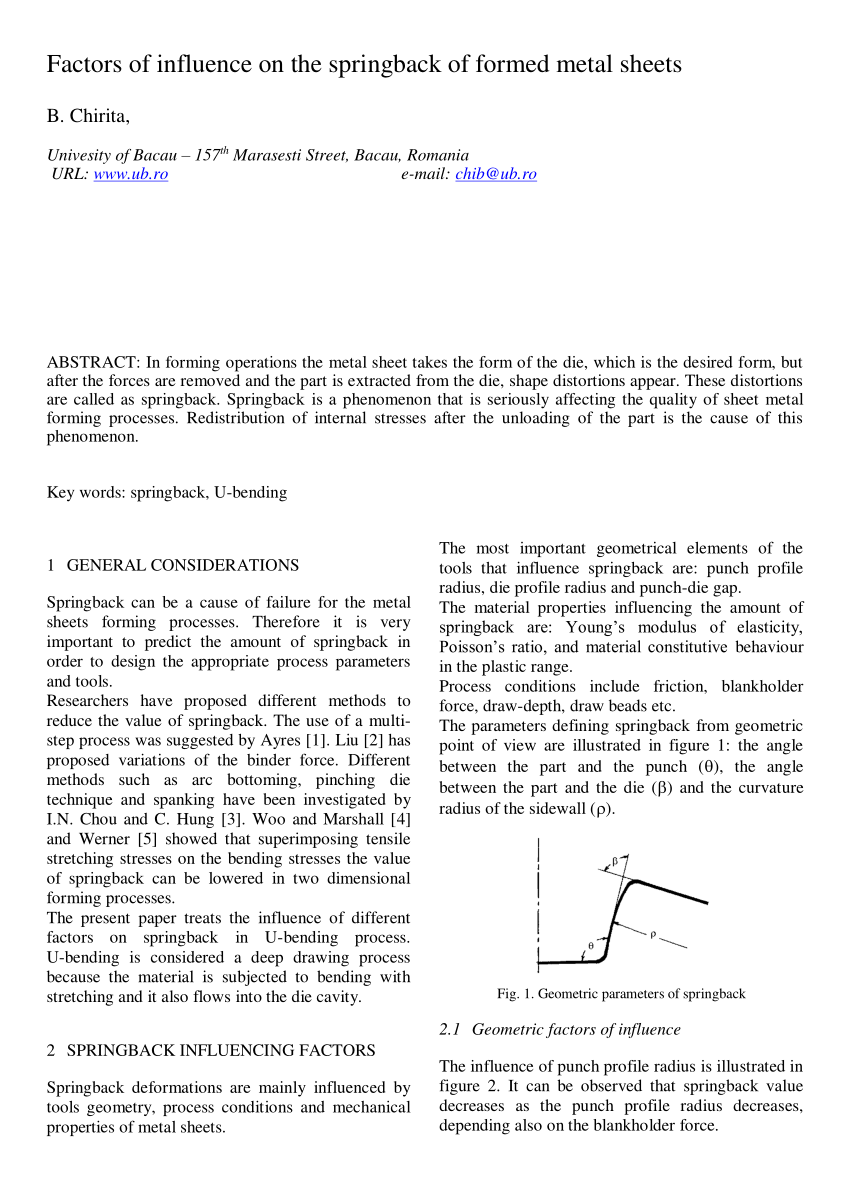

Another attractive possibility dealing with springback problems regards the integration between optimization techniques and numerical simulations in order to control predict and minimize springback amount in sheet metal forming operations.

Tried to reduce springback in l bending by using the optimization of die radius clearance step height and step distance.

In particular some researches focused on die compensation methodologies.