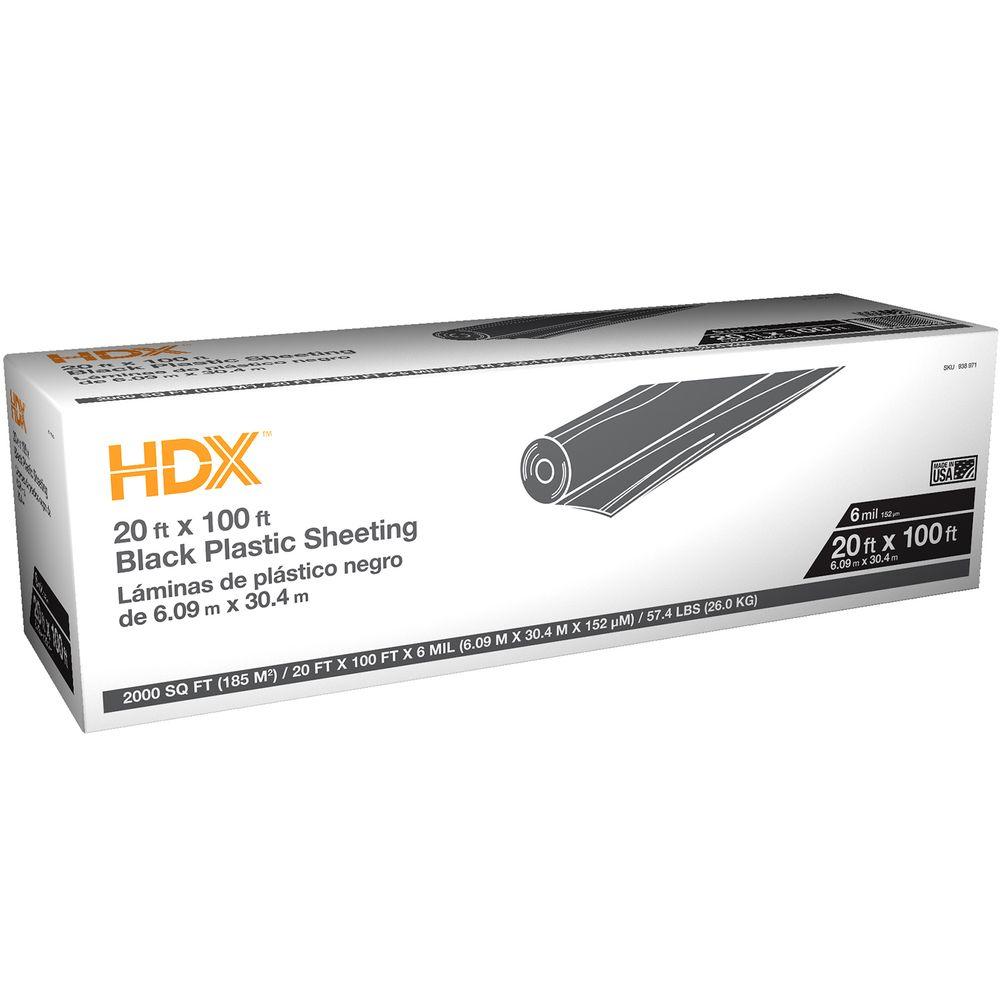

Hdx black plastic sheeting is a general purpose construction grade polyethylene film that is produced for non food contact applications.

Melting temperature of hdx black plastic sheeting.

Plastic sheeting is a general purpose plastic film for use in a variety of construction and diy projects.

Plastic the hdx 20 ft.

This heavy duty plastic can be used to cover crawl spaces and as a temporary cover for equipment and supplies.

Although there are no phthalates styrene or bisphenols in the resins that produce this plastic a better choice for this application might be a landscape fabric that is more permeable and will withstand the.

This information should be used as an on the spot reference only.

Plastic sheeting is a general purpose plastic film for use in a variety of construction and diy applications.

Pet is generally extruded to produce films and sheets can be thermoformed after.

No 3 hours at 105 110 c 221 230 f for regrind.

At curbell we offer a variety of high performance plastics for extreme temperatures including ultem radel r peek poletheretherketone and dupont vespel.

Screw with an l d ratio of 18 22 is recommended.

Place the plastic sheet on a cookie sheet and place in an oven set to 250 f.

The hdx 10 ft.

Minimum service temperature 40 c melting temperature 165 c 3146 service temperature short term 140 c service temperature long term 105 c heat distortion temperature hdta process 96 c 75 2 thermal expansion clte 23 60 c 1 1 10 4 1 k 53752.

Higher melt temperatures are needed for extrusion coating 280 310 c a three zone screw with an l d ratio of around 25 is recommended.

Users should always follow the material suppliers processing data sheets.

Advances in polymer technology have extended the operating temperature range of plastic materials so that they can now perform in conditions that are colder and hotter than ever before.

When it s ready you ll find it flexible when you try to pick it up.

7 put on your gloves when you work with the plastic.

Wait about 10 minutes for it to warm fully.

Commonly used as a vapor barrier in between insulation and drywall.

140 160 c to obtain a crystalline pet for technical applications for transparent applications mold temperature should lie between 10 and 50 c.

Plastic the hdx 10 ft.

The hdx 20 ft.