The rule of thumb in stamping design is to leave a minimum of 1 1 2 times material thickness between trimmed or perforated features.

Maximum thickness for sheet metal stamping.

For noncircular sheet metal parts the maximum diameter is sometimes used.

Many different types of metal can be cut and formed in a die.

Shearing material thickness range varies from 0 125 mm to 6 35 mm 0 005 to 0 250 in.

But designers design sheet metal parts considering sheet thickness in mm.

Typical sheet metal thicknesses used in stamping are 0 001 in.

Also watch out for punch deflection especially if you re working with small hole diameter to material thickness ratios.

Thickness to diameter ratio is a main factor used to quantify the geometry of a blank and can be calculated by t d b.

At the same time an iron oxide film is formed on the surface.

Sheet metal thickness is an important aspect of deep drawing process design.

Thickness is represented by t and d b is the diameter of the blank.

Shears are used as the preliminary step in preparing stock for the stamping processes or smaller blanks for cnc presses.

Also the stretching and compression of forming can distort holes adjacent to a form or bend.

Material selection is a very important part of product design.

Although most stamping operations use sheet steel special dies can cut and form steel bars up to 3 in.

Steel above 25 gauge steel 0 020 0 56 mm thick is considered heavy gauge.

Manufacturer provide sheets thickness in gauge.

Thicknesses in excess of 0 5 inches are above the gauge scale and measured in inches or millimeters of thickness.

Through my website someone from a manufacturing company asked how to calculate thinning in a sheet metal part made from 2mm thick high strength steel.

The cold rolled continuous hot dip galvanized steel sheet and steel strip having a thickness of 0 25 to 2 5 mm are first subjected to a flame heated preheating furnace to burn off surface residual oil.

Holes are best kept at least 2 times material thickness beyond the radius of a formed feature.

But this is just the aim thickness.

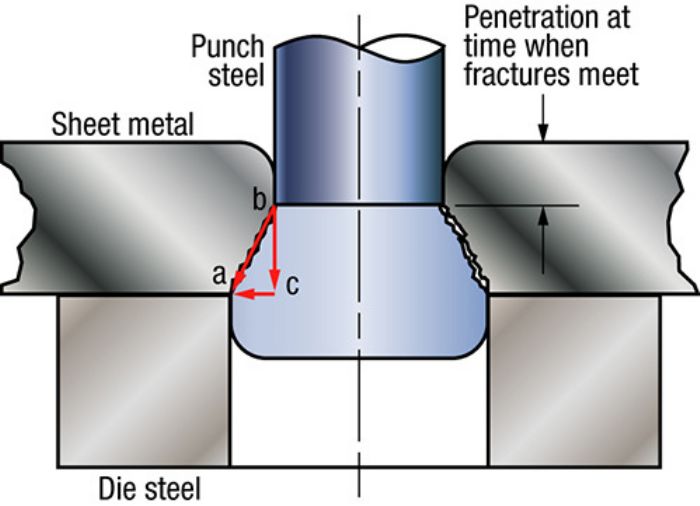

Metal stamping is the process of blanking or forming components from metal sheets.

The steel mill is allowed to ship product that has some.

The various gauges of sheet metal range from the thinnest 38 gauge 0 0063 0 16 mm thick foil to the thickest 7 gauge 0 5 12 70 mm thick plate steel.

The dimensional tolerance ranges from 0 125 mm to 1 5 mm 0 005 to 0 060 in.

Maximum sheet metal punching minimal distortion.

Which serves the metal stamping market with the latest technology advancements.

It has impact on sheet metal part design as well.