Plywood is a powerful structural product used where plywood is a powerful structural product used where strength and stiffness are required for subfloors wall or roof sheathing and do it yourself projects.

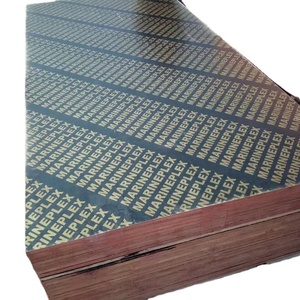

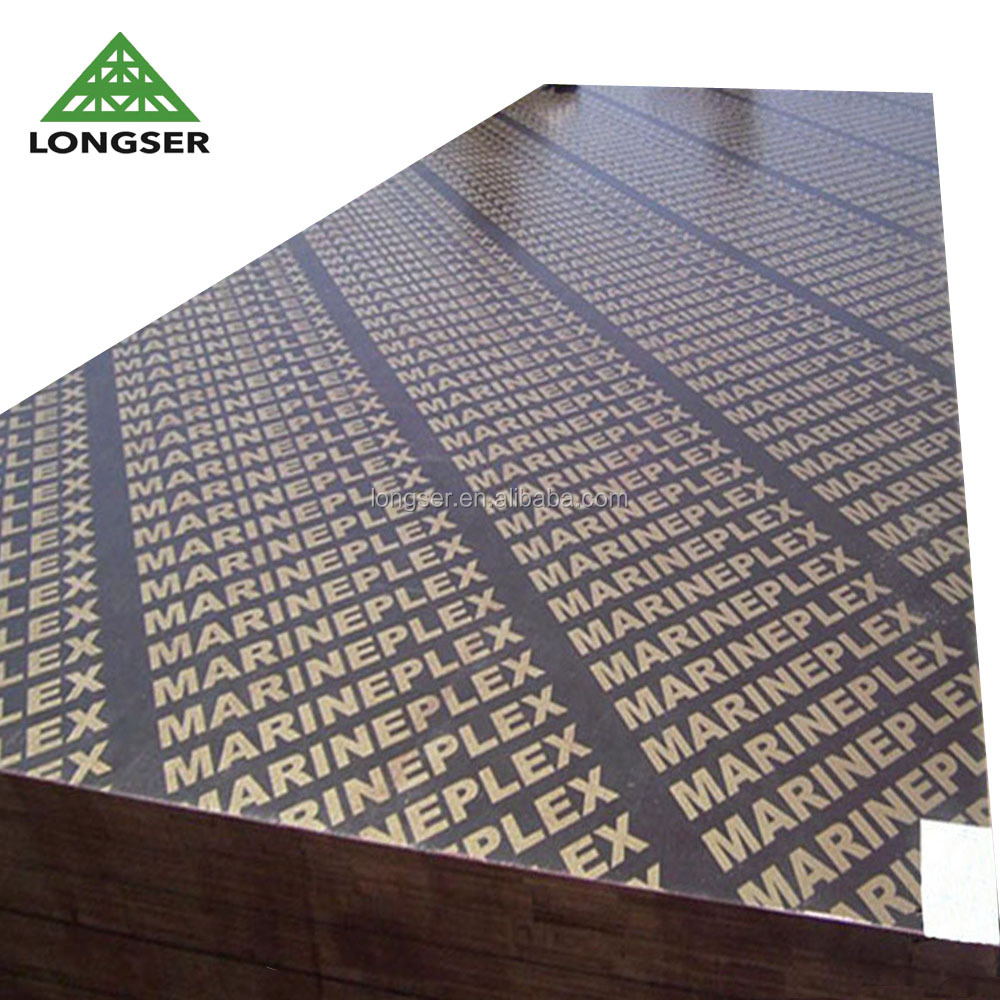

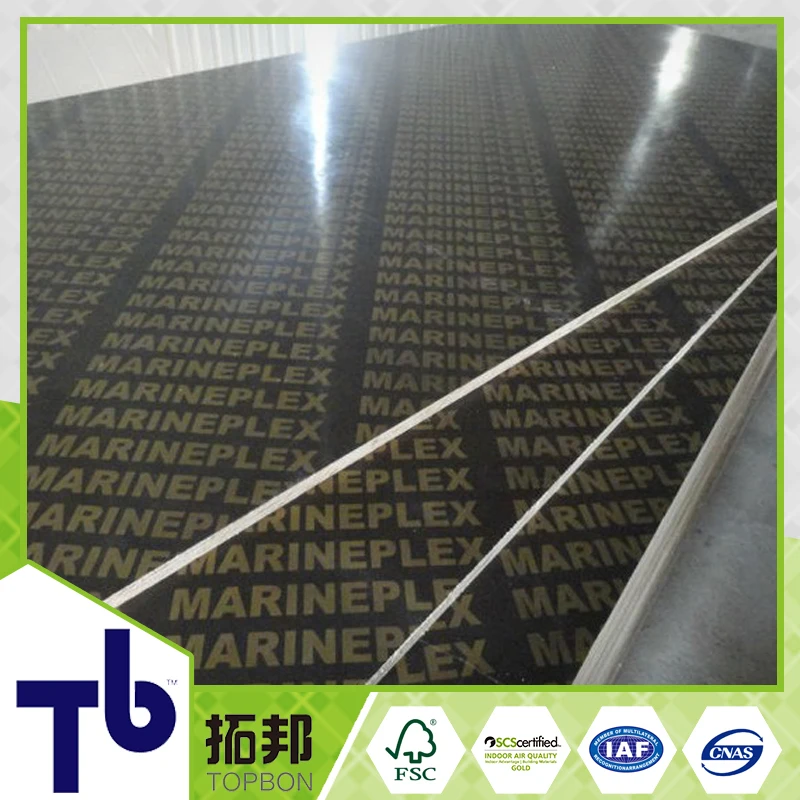

Marineplex plywood data sheet.

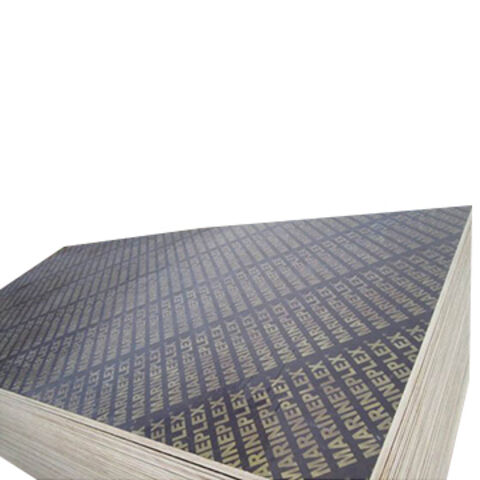

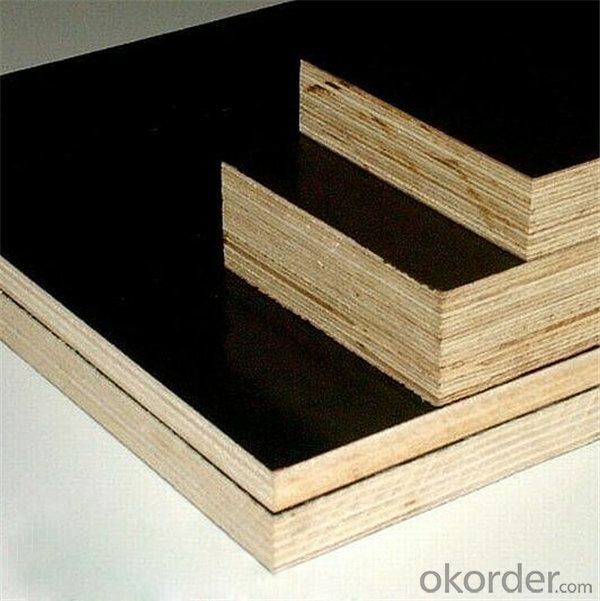

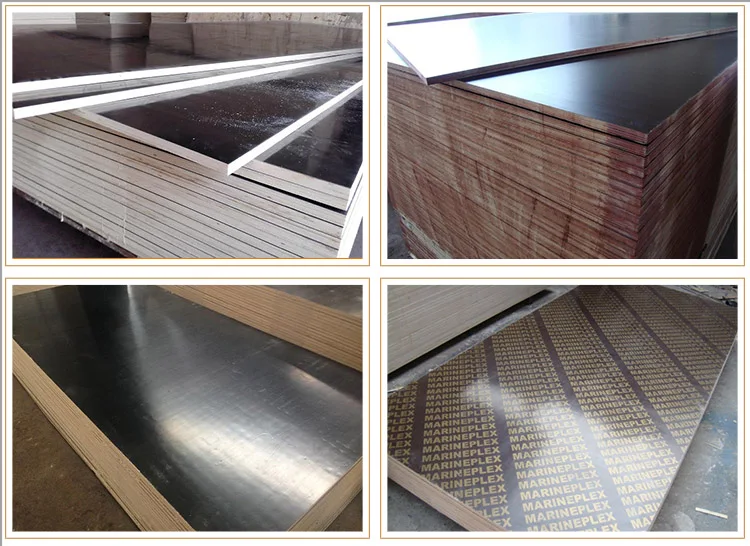

Manufactured from thin sheets of cross laminated veneer and bonded under heat and pressure with strong adhesives plywood panels have superior dimensional stability and an excellent strength to weight ratio and are highly resistant to impacts chemicals.

547 items found for marineplex plywood.

You can also choose from first class third class marineplex plywood as well as from none 1 year and more than 5 years marineplex plywood and whether marineplex plywood is e0 e2 or e1.

Marine grade plywood is perfect for use in the marine industry where greater moisture applications requiring a high quality face and back that is factory sanded and ready for further finish.

Www plywood cn inspect and export by xuzhou roc interbational trading co ltd.

Marine plex plywood marineplex plywood marineplex film faced plywood manufacturer supplier in china offering marine plex plywood marineplex plywood nfp bl1001 10mm 60mm bulk blank white or black 100 polyester lanyard fabric for dye sublimation or heat transfer printing high quality 100 polyester lanyards white or black blank 10mm.

The marine grade plywood is sanded on both faces.

Slow growing inland douglas fir and western larch yield fine grained smooth faces.

Shanghai newswan international trading co ltd.

Film faced plywood with high quality export to australia use for formwork concrete export film faced plywood to middle east formwork whosales produce by xuzhou liferng timber industry co ltd.

Comparing marineplex plywood prices you can buy quality marineplex plywood at factory price low price in china.

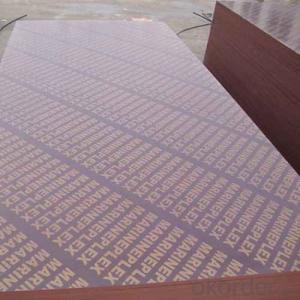

Marine plywood manufactured to as nzs 2272 standard is a structural plywood intended for hulls of boats and other marine applications.

Plywood is made of layers of thin sheets of veneer in alternating wood grain directions which increases the strength and stiffness of the final panels while providing superior dimensional.

It has a type a wbp phenolic bond glue and is manufactured from woods based on density bending strength impact resistance and surface finishing characteristics.

The maximum core gap size permitted is 1 8 inch.

Faces marine grade faces shall be limited to a total of nine repairs in a 4 x 8 panel.